Proper ventilation is critical to the safe and efficient operation of commercial kitchens. Components such as grease duct, grease hood and commercial oven hood play crucial roles in removing contaminants, preventing fires and maintaining a healthy work environment.

Grease Duct: Grease conduits

What is a Grease Duct?

Grease ducts These are conduits specifically designed to transport vapors and grease particles from exhaust hoods to a safe discharge point. They are built to withstand high temperatures and prevent the build-up of grease, which can be flammable and pose a fire risk.

Importance of correct installation

The correct installation of grease ducts is crucial to ensuring the efficiency of the exhaust system and the safety of the kitchen. They must be designed and installed in accordance with safety standards to avoid leaks and grease accumulation. Regular inspections and cleaning are also necessary to maintain system functionality.

Grease Hood: Grease Hoods

Function of grease hoods

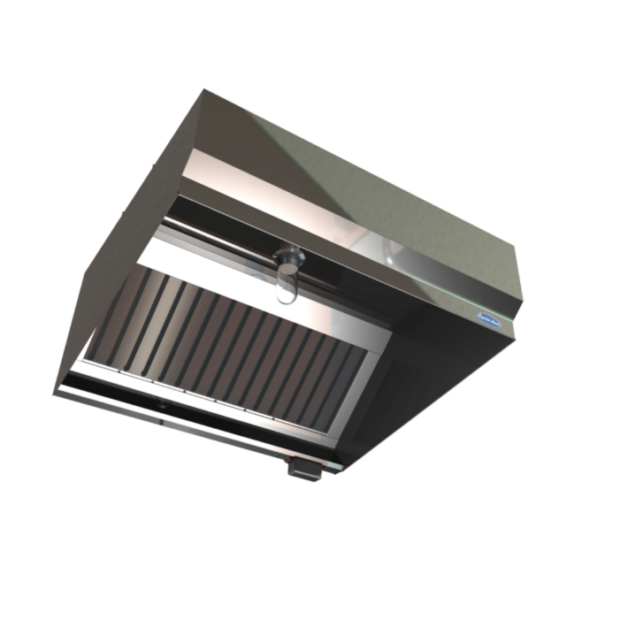

Grease hoods These are ventilation hoods designed to capture vapors, smoke and fat particles generated during cooking. They are essential for maintaining air quality in the kitchen and preventing the accumulation of grease on equipment and surfaces, which can be a fire risk.

Types of Grease Hoods

There are several types of grease hoods available, including wall-mounted and island hoods. Choosing the right type depends on your kitchen layout and specific exhaust needs. Well-designed and dimensioned hoods guarantee the efficient capture of contaminants and contribute to the safety and hygiene of the kitchen.

Commercial Oven Hood: Hoods for Commercial Ovens

Need for Commercial Oven Hoods

Commercial oven hoods These are specific hoods for commercial ovens, designed to remove heat, smoke and vapors generated during the use of ovens. They are essential for maintaining the appropriate temperature in the kitchen and ensuring employee safety.

Benefits of Commercial Oven Hoods

These hoods help improve air quality, reduce the risk of fires, and increase employee comfort. They also help extend the life of equipment by preventing the accumulation of grease and residue in ovens and surrounding areas.

The interconnection of exhaust systems

Component integration

Exhaust systems in commercial kitchens are made up of several interconnected components, including grease ducts, grease hoods and commercial oven hoods. Each component plays a specific and essential role in removing contaminants and maintaining a safe and efficient environment.

Maintenance and inspection

Regular maintenance and inspection of exhaust systems are essential to ensure functionality and safety. Periodic cleaning of grease ducts and grease hoods helps prevent grease accumulation and reduce the risk of fires. Furthermore, regular inspection of commercial oven hoods ensures that the ovens operate correctly and without risks.

The Importance of exhaust systems in commercial kitchens

Investing in quality components such as grease ducts, grease hoods and commercial oven hoods is essential for the safe and efficient operation of commercial kitchens.

These systems help maintain air quality, prevent fires, and create a safer, more comfortable work environment for employees. By ensuring proper installation and regular maintenance of these components, commercial kitchens can operate more efficiently and safely, providing high-quality service to their customers.